Not known Factual Statements About gearbox cvt

Not known Factual Statements About gearbox cvt

Blog Article

For eCVTs, the primary get worried often talked about is driving boredom, since they don’t give the same sporty experience as other transmissions.

There are some explanation why you may want a car by using a CVT gearbox, but Additionally, there are some likely downsides which might be well worth becoming aware about.

It was a sunny Saturday afternoon when Dan chose to consider his vintage 1965 Mustang for the leisurely cruise…

A consistently variable transmission in the car senses the accelerator enter with engine load and get shifted to the specified velocity or torque equipment ratio instantly, Basically we can express that a cvt transmission has become the easiest different types of automated transmission that gives constant uninterrupted electrical power inside a specified range of velocity and torque ratios.

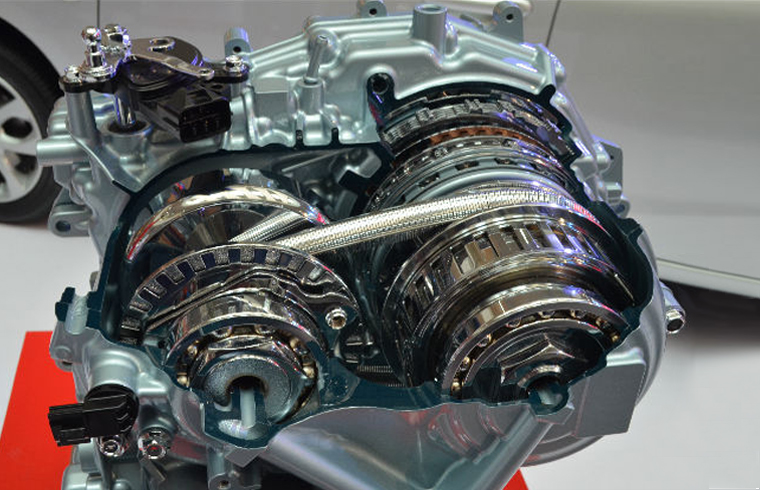

The most common sort of CVT takes advantage of a V-belt which operates among two variable-diameter pulleys.[two] The pulleys consist of two cone-shaped halves that go together and apart. The V-belt operates amongst these two halves, so the helpful diameter in the pulley is depending on the gap involving the two halves of the pulley.

In this post, we will discover how a CVT functions in a normal rear-wheel pushed motor vehicle, answering a number of inquiries on how:

Winches and hoists are also an application of CVTs, especially for All those adapting the transmission ratio on the resistant torque.

Improved Driving Experience: The continual adjustment with the gear ratio assures a seamless transition among speeds, providing a more comfortable and pleasing push.

Increasing the gap lets the belt to experience deeper inside the “groove”, terus ke sana Consequently effectively lowering the pulley sizing. Lowering the hole has the other effect; the belt rides greater, as if in a bigger pulley.

Le Tutorial de l'automobile est le stage de repère par excellence du domaine automobile au copyright. Il offre des nouvelles, des critiques et des vidéos exclusives ainsi que tous les détails sur les nouveaux véhicules et les véhicules d'event.

Variable-diameter pulleys should often are available pairs. One of the pulleys, called the push pulley (or driving pulley), is linked to the crankshaft with the motor. The driving pulley is also known as the enter pulley mainly because it's where by the energy in the engine enters the transmission.

If you're a information junkie with the vehicle market, you'll see that about the system of a number of years in the past, Nissan’s gains plunged because the sale of the corporation’s autos had trended to go in the incorrect direction. Nissan has started to tackle the problems connected with CVT transmissions. From shuddering and shaking to slipping and overheating, Nissan CVT transmissions have been acknowledged to working experience An array of difficulties that will effect efficiency, protection, and General driving working experience.

The gap among the center from the pulleys to exactly where the belt tends to make contact in the groove is known as the pitch radius. In the event the pulleys are significantly aside, the belt rides reduced and also the pitch radius decreases. When the pulleys are shut jointly, the belt rides increased as well as the pitch radius raises. The ratio of the pitch radius over the driving pulley to your pitch radius about the driven pulley determines the gear. HowStuffWorks When one pulley will increase its radius, the opposite decreases its radius to help keep the belt restricted. As the two pulleys change their radii relative to one another, they create an infinite range of equipment ratios -- from very low to significant and anything in between.

The design basic principle dates back again to ahead of the 1930s, with the original style intended to change rotary motion to oscillating motion and back again to rotary movement employing roller clutches.[eighteen] This structure continues to be in production as of 2017, for use with small-pace electric powered motors.